teebone110

Distinguished Member

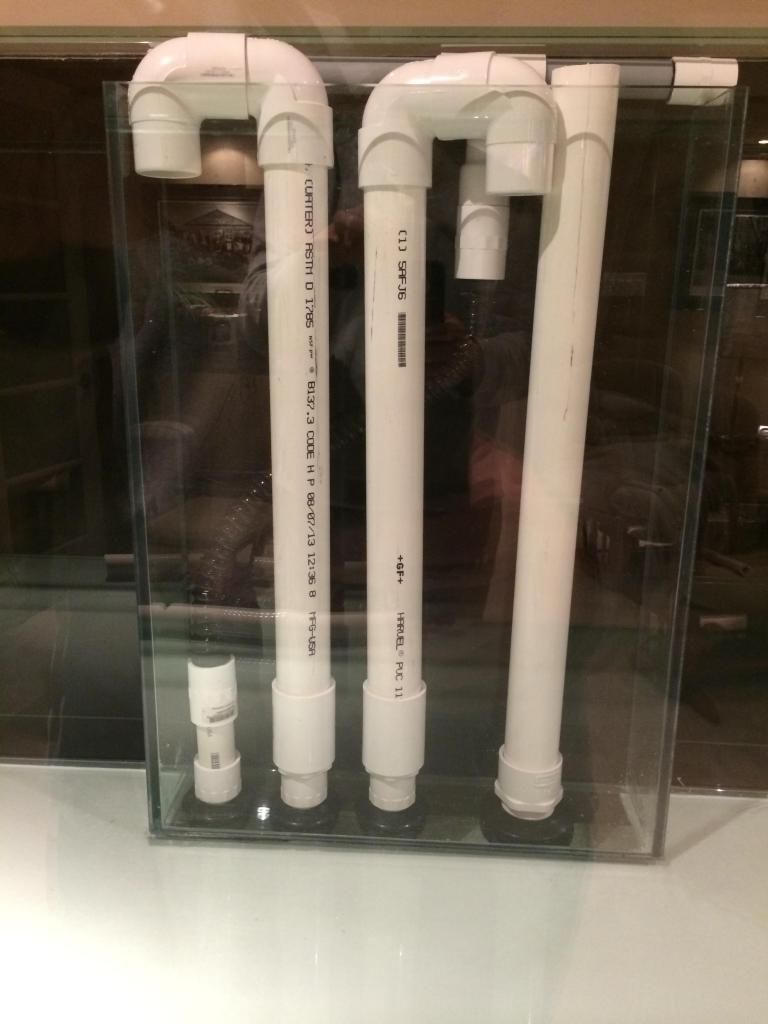

The snake eye

Sent from my iPhone using Tapatalk

Now where can one find one?

The snake eye

Sent from my iPhone using Tapatalk

Nice! I was just wondering the other day how your upgrade project was coming along.

Solid build bud!!! I love the planning involved

Any idea if you gonna use dry or live rock

Ya I just got my pukani rock and shelf from Eli at Fiji gonna do my acid dip tomorrow what ratio did you use with your dip I did a small like 1:20 with some rubble for a test and didn't get much results

Lots of bubbling but still lots of organic matter

I could never fit my hands in there! That is very compact! Overflow looks good. Any problems trimming it?

Sent from my iPhone using Tapatalk

Thanks, I have literally looked at hundreds of designs to come up with this one,Looks great Tyler!

Also agree with J_T - I could NOT fit my hands in there! Props.