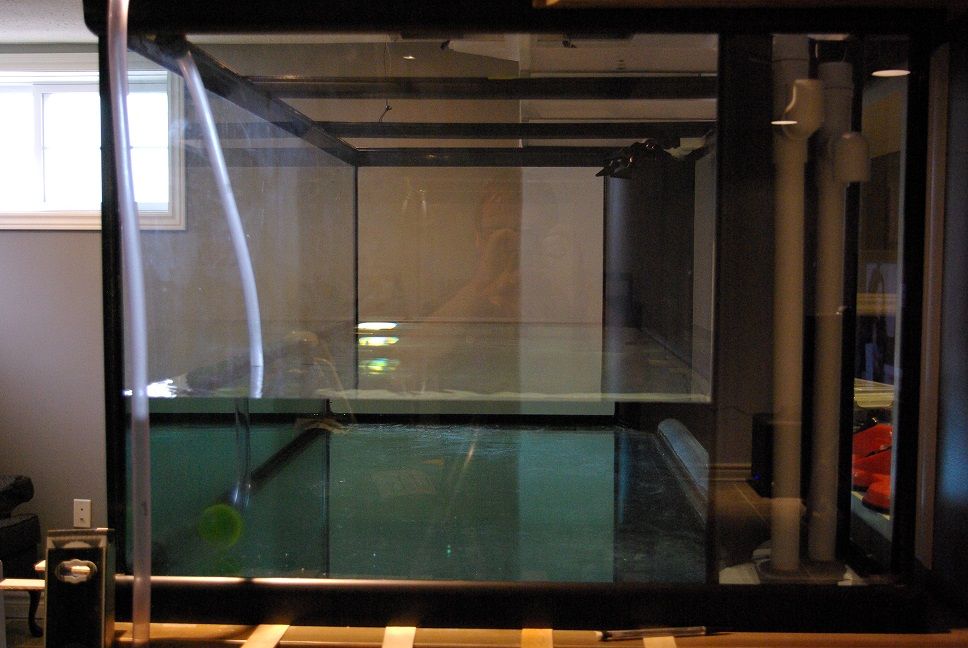

Plumbing is finished, overflows are now tied into one another. Leak tested and performance tested the build. Everything passing just need to raise up my bean animal system to minimize the drop over the overflows.

You can see the channel running along the bottom of the tank, connecting the two overflows. I used 2" pvc cut lengthwise in half which gives me a little more than the cross sectional area of the 1" drain lines that I used for the bean animal drains. The level that you see the drains at will be raised by 2.5" to minimize the sound of the water flowing into the overflows. With my dc pump the only sound there is is this slight drop, very impressed with the system.

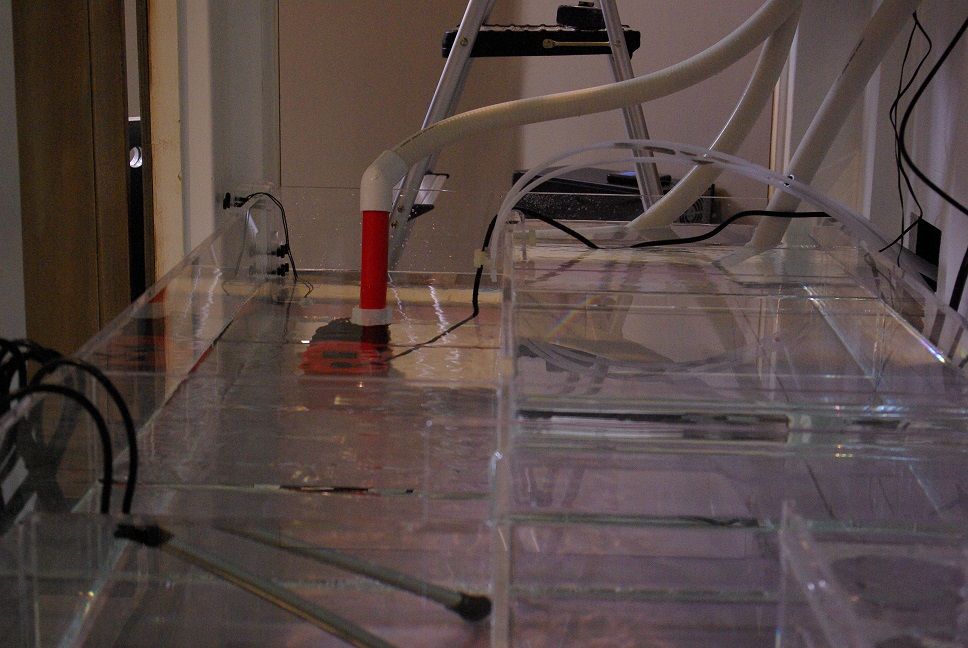

At this point I found one leak, a union that was not tightened down all of the way, my bad, easy fix

.

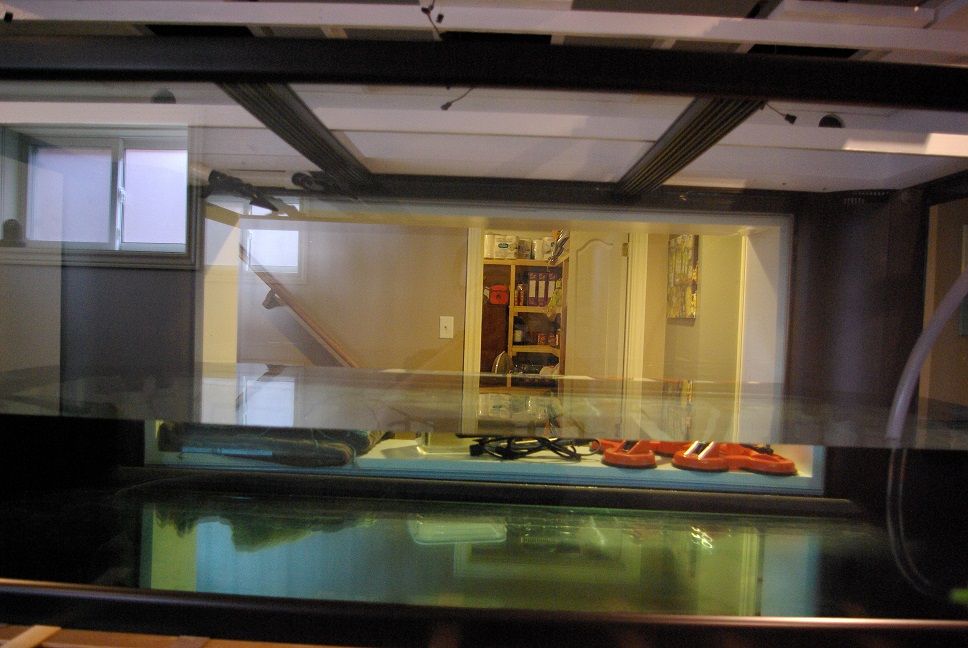

Very simple plumbing job, I have a 1" gate valve on the siphon line that will be used to fine tune the siphon to match the return pump the ball valves that follow simply allow me to direct the flow towards the skimmer area of the sump or the refugium area. Trickle and emergency lines get no valves as they do not need to be tuned. No valves on the return line as the DC pump allows me to choose from one of 6 flow rates which will suit my purposes just fine. Literally dead silent in the sump area, great sump design to pat myself on the back, thanks again to JT Custom Acrylics for building me this dream sump.

Not alot of headspace in the sump when running, my calculations worked out perfectly, powering down the system leaves me with 1" of extra volume before any flooding. I may have a cover fabricated to minimize the amount of evaporation as this is almost as much of a footprint as the display.

In other news I have beta fitted the wiring and tested the diy LED fixtures. Loving the cloud effect and versatility of the Storm X led controller. Going to see if I can work on the lighting and get a video posted in the next week or two.